There are various types of electrical wires available that differ in their insulation material and copper construction, which determine their suitability for specific applications. Let us take a look at each one of them to help you choose the correct wire for you.

Classification Based on Copper Construction

- Solid Copper Wire: Solid copper wire is a single, solid strand of copper wire. It is commonly used in building wiring, such as for electrical outlets and switches. It is also used in overhead power transmission lines due to its high conductivity and strength.

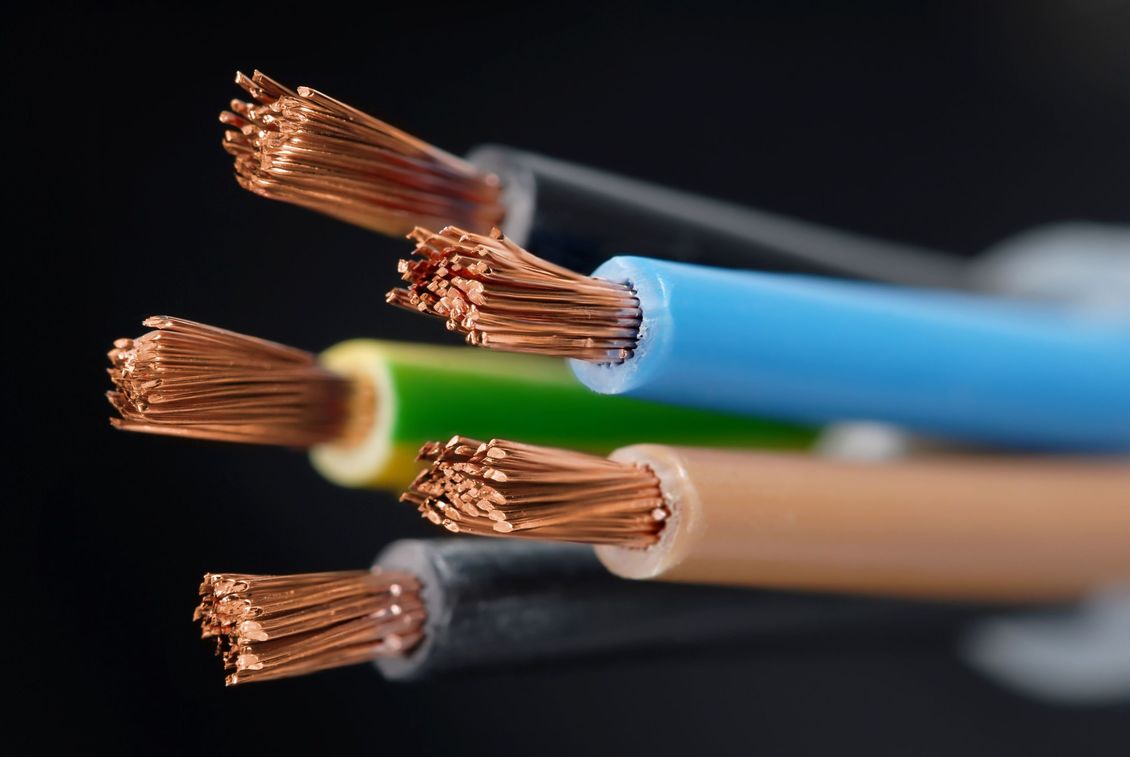

- Stranded Copper Wire: Stranded copper wire is made up of multiple small strands of copper wire that are twisted together. This type of wire is more flexible than solid copper wire, making it easier to work with and install. It is commonly used in applications such as speaker wire and electronic devices.

- Tinned Copper Wire: Tinned copper wire is coated with a thin layer of tin, which helps to protect the copper from corrosion and oxidation. It is commonly used in marine and automotive applications due to its resistance to saltwater and other corrosive elements.

- Copper Clad Aluminum Wire (CCA): CCA wire is made up of an aluminum core that is coated with a thin layer of copper. It is a cost-effective alternative to pure copper wire, as it provides similar electrical conductivity at a lower cost. However, CCA wire is not as durable as pure copper wire and can be more prone to breakage.

Classification Based on Insulation Material

1. FR PVC Copper Wire (Flame Retardant):

This is the most common type of electrical wire available that is insulated with flame retardant PVC. This means that it resists or slows down the spread of fire. It is the most used wire in households, commercial buildings, theatres, and public places. However, these wires have a high impact on the environment and human health as their PVC contains Lead, which is toxic heavy metal. At Relemac we do not use PVC that contains lead due to its high impact on the environment and human health.

2. FRLF PVC Copper wire (Flame Retardant Lead Free):

These wires have the same properties as FR PVC Copper Wires but do not contain lead in their PVC insulation. FRLF PVC insulation is made using calcium or zinc or both which gives strength and durability. In many countries, including the United States and the European Union, regulations limit or disallow the use of lead in PVC products, which has led to an increase in the use of lead-free PVC. All the wires and cables of Relemac are made of Lead Free PVC Only i.e., all our products are 100% Lead Free.

3. FRLS PVC Copper Wire (Flame Retardant Low Smoke):

These wires are insulated with PVC material that is both flame retardant and low smoke emitting. In case of a fire, it produces less smoke, which reduces the risk of suffocation and improves visibility. It is commonly used in densely populated areas, such as hospitals, schools, and high-rise buildings.

4. ZHFR PVC Copper Wire (Zero Halogen Flame Retardant):

These electrical wires are insulated with PVC material that is both flame retardant and emits zero halogens. This means that it does not emit toxic halogen gases when exposed to fire or high temperatures, making it safer for humans and the environment.

Conclusion: Choosing the right type of electrical wire is crucial to ensure the safety and efficiency of your electrical system. Consider the insulation material and copper construction when selecting a wire for your specific application. At Relemac, we provide a wide range of wires and cables that are made using high-quality, lead-free PVC insulation and pure copper construction to ensure the safety and longevity of your electrical system.

Leave a Reply